ITW Construction Products Offsite, using their proven method of Customer-Back Innovation and listening to market challenges, have created a brand new industry solution – Gang-Nail Truss Frame*.

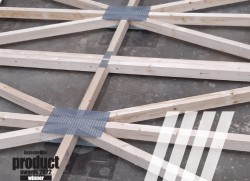

Known as the innovative alternative to traditional timber frame walls, Gang-Nail Truss Frame recently won the 'Best Brand New Product' in the Housebuilder Product Awards 2022. This new solution is a system of standardised wall elements made offsite, that combine into larger modules on-site. The Gang-Nail Truss Frame wall elements are made up of timbers pressed together at the joints using Gang-Nail nail plates. This new solution has been in development for over two years and addresses many market challenges including:

Shortages and Cost of OSB

Gang-Nail Truss Frame gains its structural strength and superior resistance to wind-loading from the design and the use of Gang-Nail nail plates for the joints of the timbers. This eliminates the need for OSB, currently used to provide structural integrity to traditional timber frame walls. This means the elimination of panel nailing and OSB, and the associated use of synthetic resins and waxes.

U-values

The Gang-Nail Truss Frame structure allows a lesser amount of insulation to be wrapped around the wall panel's external face, eliminating thermal bridges and saving on material. U-values of 0.18 W/m²K and lower are easily achievable, meeting new Part-L standards.

The Shift Towards Offsite Manufacturing

The Gang-Nail Truss Frame wall elements are designed to be made offsite, meaning they can be manufactured in a controlled environment. This helps meet the government's pre-manufactured value (PMV) threshold of 55% for the Affordable Homes Programme.

Efficiencies in Manufacturing

Since the Gang-Nail truss Frame wall elements are made offsite in a controlled environment where the process of making the panels is the same every time, efficient manufacturing is pretty much guaranteed. With the elimination of cutting and nailing of OSB, potential bottlenecks in the production process are removed. The need for double sheathing is eliminated and safety is enhanced as there is no possibility of nails hitting nails.

Complexity in Design Calculations

Gang-Nail Truss Frame structural elements have pre-defined values based on external testing of the panels. This means building designers can rely on the published values all the way through from design to on-site construction. This also simplifies calculations in case of re-design, saving time and reducing complexity.

*Patent Pending

Source: https://issuu.com/radarcommunications/docs/offsite_mag_iss_32_76pp_web/30?e=15424601/64704172