Drywall Steel Sections Ltd. (DWSS) is a manufacturer of Light-Gauge Steel Infill and Loadbearing products, Pre-panelised SFS frames, and Drywall products (internal non-loadbearing). Their unique approach in manufacturing these products involves an unrivalled manufacturing lead time, as well as a project-first approach to customer service.

Light-Gauge Steel manufacturers have a responsibility to perform fire tests on several wall and floor construction types. Fire testing different build-ups with various board and insulation manufacturers offers designers, contractors, and developers a wide range of flexibility and choice. Due to the ever-evolving legislation and results of the tragic events surrounding Grenfell, it has never been more important to vigorously test these important parts of a construction. Drywall Steel Sections Ltd. committed and invested in a stringent ongoing fire testing programme, starting with the first 5 tests in 2021.

A spotlight was directed at the Façade sector – what are the testing strategies? Is the right product or material being utilised for the appropriate application? Have we got absolute evidence that this proposed system will perform as expected? If the products used in construction have a direct or indirect association with the external envelope of a building, how do each of these products implicate each other with regards to the fire protection?

DWSS's customers wanted confidence that the products they were being delivered from their factory were compliant and tested materials, especially if there was a particular fire strategy requirement on their project. They wanted visibility on the actual fire test data. This was a key driver for DWSS to undertake fire testing to further enhance our offering to our customer base and ultimately the people who would live and work in these buildings.

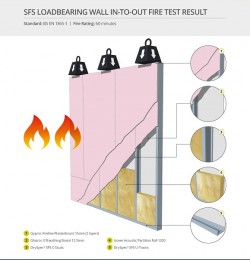

Over the course of September and October 2021, DWSS conducted the following 5 fire tests with Dryspec® SFS, at the British Research Establishment (BRE) in Watford:

- SFS Loadbearing Wall In-to-Out = 60 minutes

- SFS Loadbearing Wall Out-to-In = 90 minutes

- SFS Infill Wall In-to-Out = 90 minutes

- SFS Infill Wall Out-to-In = 90 minutes

- SFS Loadbearing Floor = 60 minutes

All fire tests were carried out with the full suite of Saint-Gobain products – Glasroc X Sheathing Board, Gyproc Fireline Plasterboard, and Isover APR 1200. The decision was made to start the DWSS fire testing programme with the highest performing and most specified products by Architects and MCs.

In 2022, DWSS will be conducting more tests at the BRE. Using a range of boards and insulation from other manufacturers such as Siniat and RCM, they are building their own portfolio of fire tests, offering their customers even more choice and cost saving options. In addition to these, they are delivering further tests with bespoke wall and floor build-ups for specific applications, offering personalised solutions for some of their construction industry partners.

DWSS has identified the importance and committed to the need for testing in the construction industry for the foreseeable future, especially for fire protection data. With the added challenge of building regulations and Part L, DWSS will continue to adapt and listen to the needs of its customers, and ultimately protect the end user.

Source - www.drywallsteelsections.co.uk